Pre-Cleaning

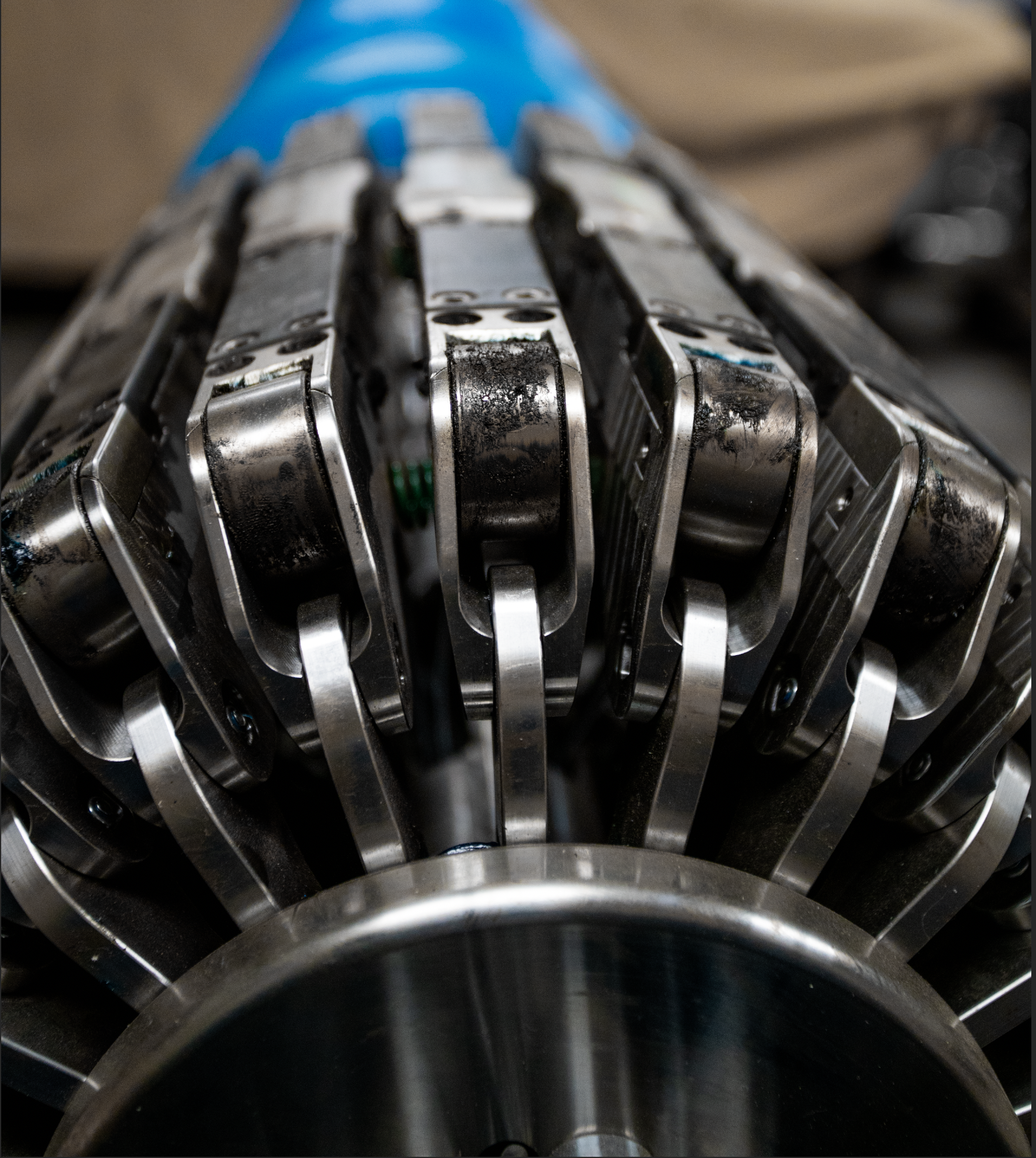

In addition to potentially damaging an expensive ILI tool, running an in-line inspection on a dirty pipeline can give you faulty data readings and necessitate costly re-runs. Our Pre-Cleaning service delivers everything you need for a successful run, from careful planning to experienced execution that include:

- pig selection (foam, wire, light-density swab, etc.) based on pipe type and size, product, current maintenance plan, and more

- best pig run frequency

- best cleaning method (mechanical and/or chemical)

and more.

ILI Propelling

Even though they’re “smart” tools, ILI equipment still requires smart operation to provide reliable results. Each tool has as an optimal run speed and different fluids work best for different ILI tool components and different applications (such as water for off-line projects). Pipeline pressure and diameter are also important considerations. Every ILI job we do is fueled by our expertise in inserting, launching, tracking, and receiving this type of tool.

Pig Tracking

Knowing where a pig is at all times during a run is invaluable, allowing for the best operation of the pig as it moves and quick response if it gets stuck. We offer non-intrusive pig detection through the use of durable, state-of-the-art above-ground markers (AGMs) by CDI that work with most ILI tools. Our personnel can identify AGM locations with extremely high accuracy, an essential capability for attaining accurate results from your inspection.